Choosing the Best Process for your Product

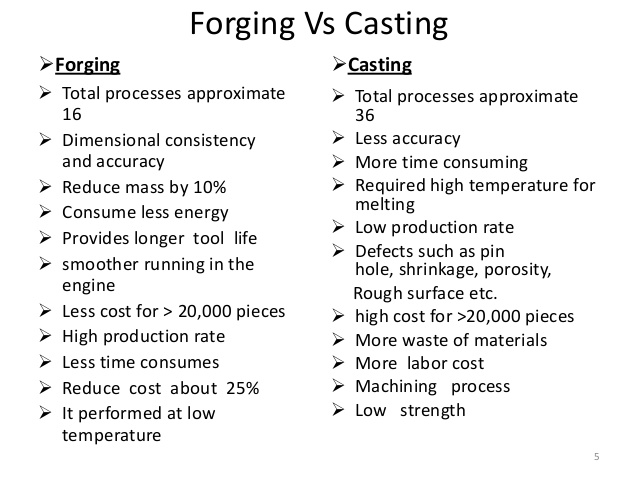

Casting is a metal modification process using molten metal poured or injected into a custom mold where it solidifies and forms a molded product. A limited amount of additional machining may be necessary to further refine the molded metal. Types of casting vary based on the molding materials and process as well as the filling pressures. Die casting,Investment casting, and Sand casting are three options for metal casting. Advantages of die casting vary slightly from those investment casting or sand casting depending on the type of materials used and the finished product that is desired.

Forging is a metal modification process that uses dies, compressive forces, and temperature to shape a solid piece of round bar metal into a desired shape. Once a piece of metal is forged, it may have to undergo further machining to add necessary detail or be subject to heat treatment or coating. Forging can be classified by the temperature used (hot, warm, cold forging), the type of process (open or closed die froging), or the type of material used (steel, aluminum, brass, or bronze forging).